Project overview

Asset Building Systems (ABS) was contracted by Abergeldie Complex Infrastructure for end-to-end project management of multiple industrial sheds for the new Water Treatment Plant at the Mount Piper Power Station (MPPS), as a part of the Springvale Water Treatment Project.

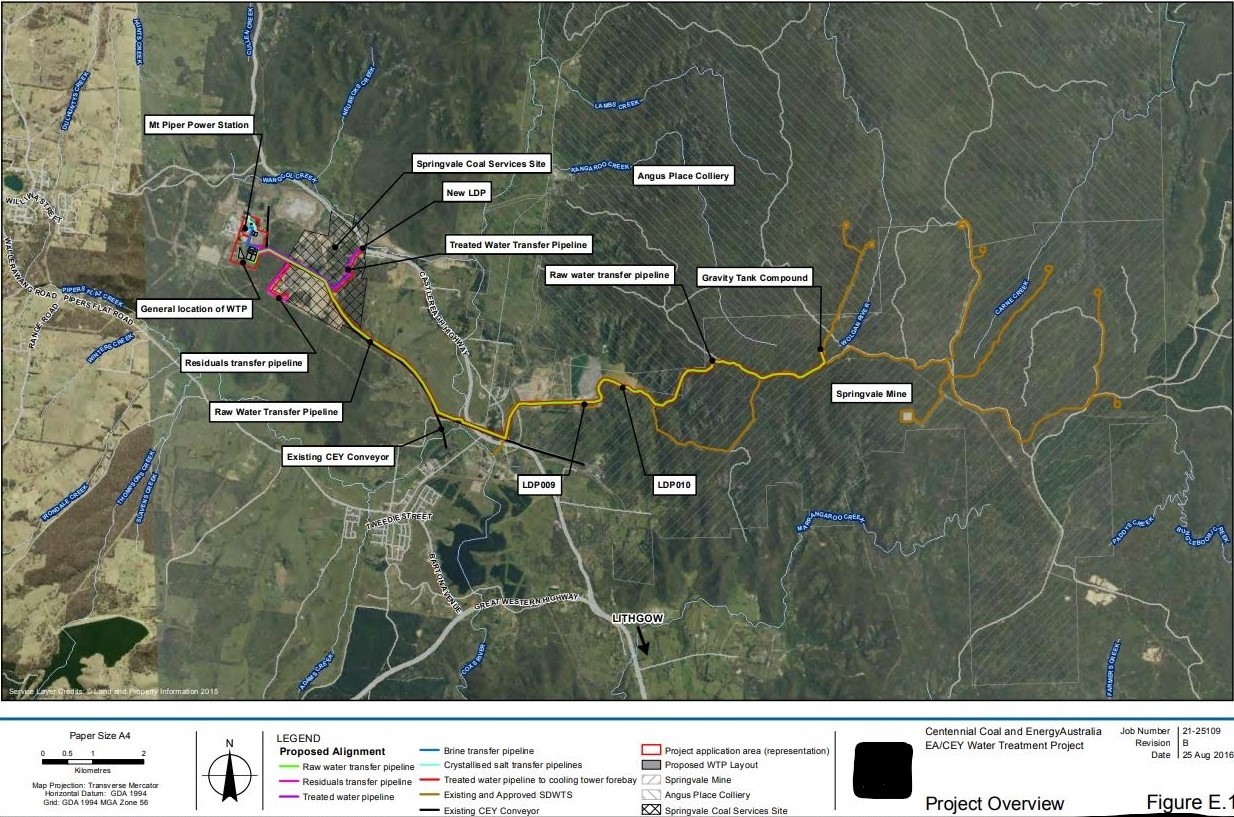

Located near Lithgow, New South Wales, the Mount Piper Power Station supplies approximately 15% of New South Wales’ power.

ABS managed the engineering, design and construction of a purpose-built reverse-osmosis shed, centrifuge building and storage sheds, for the treatment of existing mine dewatering facilities of the existing Springvale Coal Mine and Angus Place Colliery.

Classified as a NSW State Significant Development under State Environmental Planning Policy 2011, the project gained development consent with the support of an Environmental Impact Statement.

The project was catalysed by the requirement to improve environmental outcomes for the Coxs River catchment, meet the water quality performance measures for mine water discharges including desalination processes, and deliver treated water to the industrial reuse at the MPPS.

Meeting the timeframe

As a major infrastructure project with significant importance in providing energy for the State’s energy mix. The project demanded urgent delivery to meet a set deadline. Asset Building Systems was the only company who was able to provide turnkey delivery of the industrial sheds for this critical infrastructure. No other company could meet the deliverables in the timeframe that the client required. ABS rose to the challenge, building defect-free in accordance with stringent quality assurance and WHS requirements.

Our turnkey solution

Rectifying issues

During the construction phase, we noticed that footing bolts were incorrectly installed by the previous contractor. This meant the hold-down bolts were out of alignment, and the work needed to be corrected immediately to avoid compromising the project timeline.

Our team of trusted consultants worked closely with Abergeldie’s engineers to come up with a solution that involved over quarter of a ton base plate adapters and weld inspection protocols. In conclusion, we were able to adapt to changes on site, designing a special footing plate to correct the previous contractor’s mistake. Despite this, we were still able to deliver the project on time to the highest quality standards.

Our Turnkey Solution - Dirt to Done

Work with Asset Building Systems today

At Asset Building Systems, we go above and beyond to ensure that your project is a complete success.

Specialising in project management, engineering, design and construction of industrial and commerical sheds, warehouses, shed extensions and awnings for industrial purposes, such as mining, manufacturing, factory work, automotive work, retail, and more.

Dirt to Done. From compliance, to meeting strict deadlines, devising economical effectiveness to finding engineer-backed solutions for your needs, we are first-in-class.

We’d love to be a part of your next project. Contact us here for a fast budget estimate.