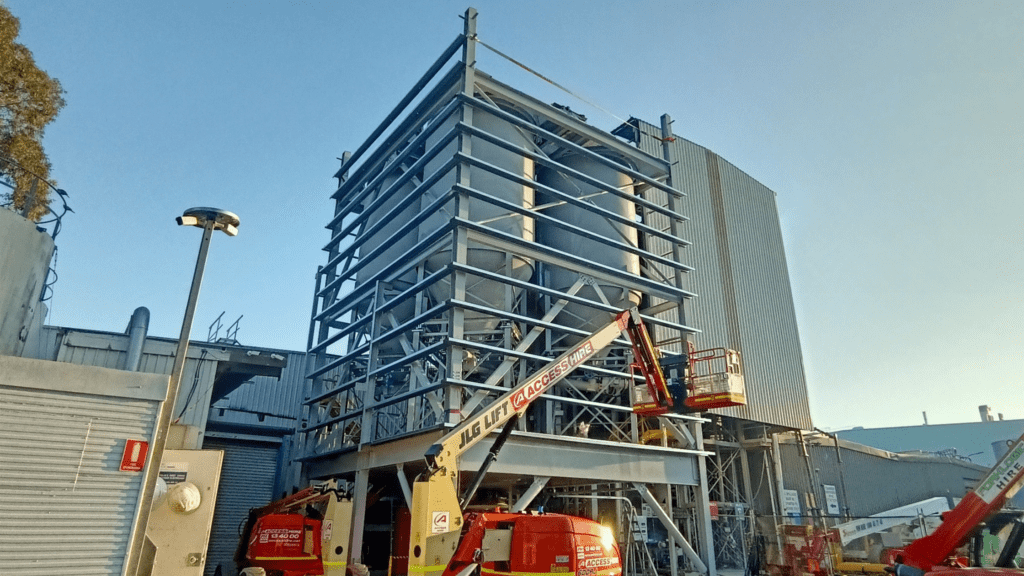

Project Name: Silo Tower

Project Overview: This project included the complete design in collaboration with the client, fabrication, and installation of the silo tower structure and silos.

Project Location: Wyong, NSW

Type of Shed/Solution: Industrial Silo Tower

Project Overview

Heavy manufacturing industries rely on durable, custom-built structures for smooth production processes. Asset Building Systems successfully designed, fabricated, and installed an industrial silo tower structure in Wyong, NSW. This project demonstrates our ability to provide turnkey industrial solutions tailored to our client’s storage and operational needs.

Our client, a major player in heavy manufacturing, requires us to build an efficient industrial silo tower system. This system needed to store raw materials and improve production efficiency. The project involved designing the structure to exact specifications, fabricating components, and performing on-site installation of the silos.

Project Scope and Objectives

The project’s scope focused on delivering a high-capacity, industrial silo tower system. We aimed to address several critical objectives:

1. Provide a customised design optimised for material storage and handling.

2. Ensure a robust, durable structure that withstands continuous operational demands.

3. Complete the project efficiently while maintaining strict safety standards.

During the planning phase, our team collaborated closely with the client to assess site-specific requirements. We conducted feasibility studies and discussed capacity needs, silo specifications, and placement. The design phase included:

• A layout optimising silo placement for streamlined material transfer.

• Structural reinforcements ensure long-term durability.

• Incorporation of safety features to protect workers during daily operations.

The design adhered to Australian safety standards for heavy manufacturing infrastructure. Our engineers ensured the structural integrity of the tower would support multiple silo installations.

Silo Tower Fabrication

Fabrication involved precision engineering and attention to detail. Our team used high-quality steel and components for maximum strength. The key steps included:

1. Cutting and Welding: Steel components were cut and welded using advanced techniques to create the primary tower framework.

2. Structural Assembly: For decreasing onsite construction time, what is needed is a pre-fabrication at our facility.

3. Corrosion Protection: All steel surfaces received protective coatings to withstand Wyong’s environmental conditions and minimise corrosion risks

On-Site Construction and Installation

The on-site construction phase required efficient project management. Our team coordinated equipment delivery, workforce schedules, and safety protocols to ensure smooth execution.

1. Foundation Preparation: We prepared the site by grading and levelling the ground. A reinforced concrete base was poured to support the industrial silo tower’s weight.

2. Tower Erection: The pre-fabricated tower sections were transported to the site and assembled using cranes and lifting equipment.

3. Silo Installation: The silos were lifted into position and secured onto the tower framework using high-tensile fasteners.

4. Safety Systems Installation: Guardrails, ladders, and platforms were installed to provide safe access for maintenance and inspections.

Safety Considerations

Safety remained a top priority during every stage of the project. The structure was designed and built following strict safety regulations. Key safety measures included:

• Pathway clearly indicated for emergency evacuation.

• Walkways and platforms fitted with anti-slip coatings to avert accidents.

• The tower was subjected to rigorous load testing to verify its capacity and stability.

Sustainability Practices

We prioritised sustainable construction practices on this project, with local materials sourced, thus reducing carbon emissions from transportation.The design of the silo tower further minimises energy by encouraging material transfer systems through the reduction of operational waste.

Collaboration with the Client

We maintained close communication with the client, holding regular progress meetings and site visits. This collaboration allowed us to address concerns promptly and incorporate feedback into the project. The client’s input was particularly valuable during the layout planning stage, where we optimised silo placement to improve workflow efficiency.

Final Inspection and Handover

Upon completion, the silo tower underwent a thorough inspection to ensure it met design specifications and safety requirements. The client and regulatory authorities approved the structure for operational use. We provided the client with maintenance guidelines and a recommended inspection schedule to maintain optimal performance.

Project Benefits

The custom-designed silo tower delivered several operational benefits for the client:

1. Enhanced Efficiency: Streamlined material handling processes reduce loading and unloading times.

2. Increased Storage Capacity: Multiple silos allow for bulk storage, supporting continuous production without disruptions.

3. Improved Safety: Built-in safety features protect workers and minimise risks.

4. Long-Term Durability: High-quality materials and corrosion protection extend the structure’s lifespan.

5. Scalability: The tower’s modular design allows for future expansions or modifications.

Future Collaboration

After the success of this project, our client expressed interest in future infrastructure work with Asset Building Systems. Our team continues in its commitment to sustaining the client’s growth with dependable and scalable solutions.

Final Thoughts

The Silo Tower project represents the ability of Asset Building Systems to provide customised solutions in the industrial sector. We guided the project from design and fabrication through to installation, ensuring all aspects including operations, safety, and environmental concerns were met. This project will continue supporting the client’s heavy manufacturing operations, driving efficiency and growth.

Looking for a custom industrial structure for your business? Contact Asset Building Systems today to discuss your project.